Products & Services

The AirReps VRV Advantage

The AirReps VRV (Variable Refrigerant Volume) Process begins with design conception and continues through site visits during construction, start-up assistance, and ongoing service. Our process is designed to improve customer satisfaction, reduce installation errors, minimize warranty issues, and ensure reliable performance throughout the equipment’s lifecycle.

The VRV Process at AirReps

At AirReps, we deliver custom HVAC solutions designed to get it right the first time. Our proven VRV Process sets us apart, combining expert design with unmatched customer care to ensure every project is executed flawlessly.

Engineering Assistance

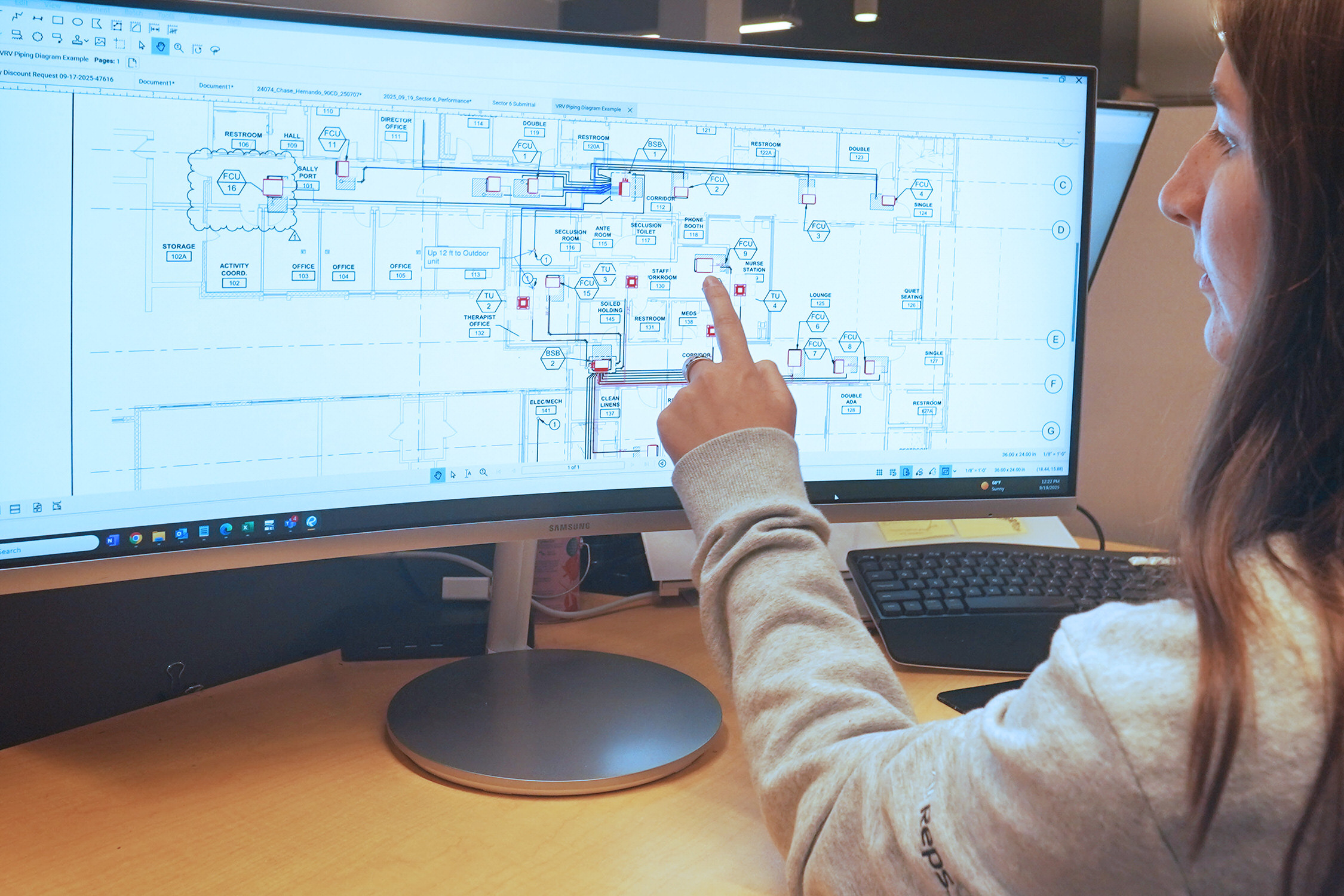

Our Engineering Team stays current through continuous Daikin VRV training, ensuring every design meets the latest standards and application requirements. Each project is delivered with consistent, clear documentation that helps consulting engineers fully understand the system.

Typical deliverables include:

- Floor plan layouts to scale, with full system visibility

- Refrigerant piping diagrams with accurate lengths and sizes

- Tagged components matching engineer designations

- Daikin design report with performance and connectivity details

- Editable Excel system schedules for easy integration

- Complete Daikin submittals (dimensions, wiring diagrams, specifications, CAD/BIM upon request)

To maintain quality, every design is peer-reviewed by two engineers to minimize issues and deliver the best possible system layout.

Project Turnover

Clear communication is critical. Once we receive notice to proceed, our team gathers all key stakeholders, including the Account Executive, Project Coordinator, Project Engineer, and VRV Team Manager, to align on project details. Final design documents are reviewed, contractual requirements are confirmed, and contractor contacts are established to ensure a smooth transition into construction.

VRV Team Kick-Off

After design approval, a dedicated VRV Specialist is assigned to the project. This specialist becomes the primary contact for the contractor’s Project Manager and field lead, guiding the installation from start to finish.

Site Visit – Pre-Construction

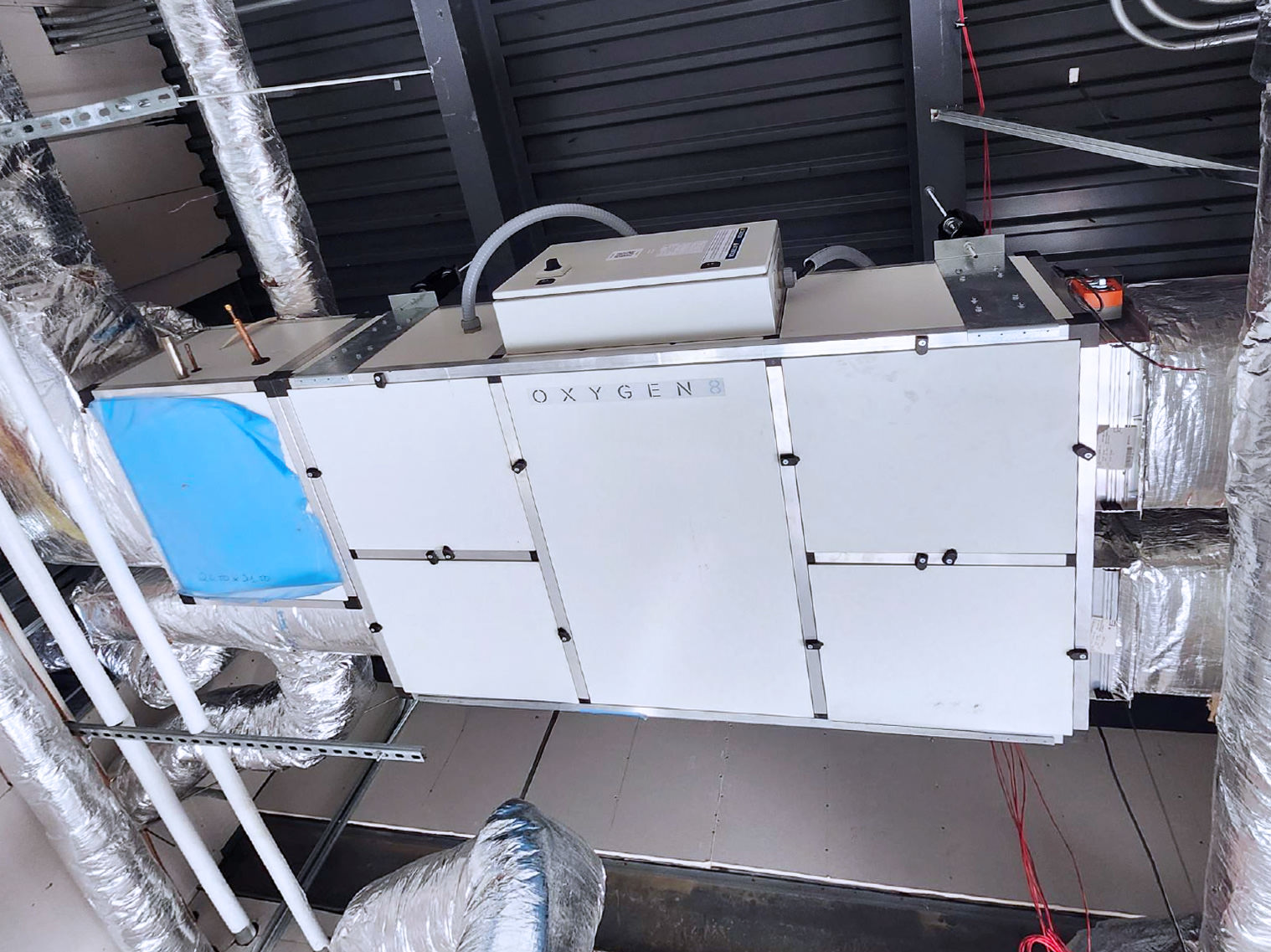

The VRV Specialist visits the site when Daikin equipment arrives. Together with the project team, they review system design, installation guidelines, and best practices, identifying any potential issues early.

Site Visit – Mid-Construction

The Specialist provides hands-on support during installation, answering questions, troubleshooting, and confirming that all materials are on site and in good condition.

Site Visit – Pre-Commissioning

Before startup, the Specialist reviews the completed installation, coordinates final measurements, and adjusts refrigerant requirements to ensure system readiness.

System Pressure Test

The VRV Team works with the contractor to complete a full pressure test, validating system integrity and preparing for commissioning.

Start-Up Assistance

Our team provides a detailed pre-startup checklist and supports the on-site technician to ensure electrical, control wiring, and all other pre-startup components are completed prior to commissioning.

Documentation

All project documentation — including system reports, backup files, and site photos — is organized and provided to the Account Executive for seamless recordkeeping and easy access.

Owner Training & Service (Optional)

AirReps offers comprehensive owner training and system servicing when requested, ensuring building operators and owners are fully supported long after installation.

Trainings & Events

Build your industry knowledge and skills.

View our lineup of in-person, hands-on technical training opportunities offered exclusively to our customers.

Our Company

The right team to get the job done.

When it comes to HVAC-related projects, you won’t find a more knowledgeable, more dedicated or better-equipped firm than AirReps.